|

Wave plates are made from materials which exhibit birefringence. The velocities of the extraordinary and ordinary ray through the briefringent material varies inversely with their refractive indices.This difference in velocities gives rise to a phase difference when the two beams recombine. At any specific wavelength the phase difference is govermed by the thickness of the retarder-waveplate.

Our wave plates (retardation plates or phase shifters) include octadic waveplates (1/8 wave plates),quarter wave plates(1/4 wave plates), half wave plates(1/2 wave plates) and full wave plates. The waveplates are widely used in synthesis and analysis of light in various states of polarization.

Half Wave plates.(see its Schematic diagram)

A linearly polarized beam incident on a half wave crystal quartz waveplate emerges as a linsarly polarized beam but rotated such that its angle to the optical axis is twice that of the incident beam. Therefore, half-waveplates can be used as continuously adjustable polarization rotators. Half-waveplates are used to rotate the plane of polarization, electro-optic modulation and as a variable ratio beamsplitter when used in conjunction with a polarization cube.

Quarter Wave plates.(see its Schematic diagram)

If the angle between the electric field vector of the incident linearly polarized beam and the retarder principal plane of the quarter-waveplate is 45,the emergent beam is circularly polarized.when a quarter waveplate is double passed, i.e. by mirror reflection, it acts as a half waveplates and rotates the plane of polarization to a certain angle. Quarter waveplate are used in creating circular polarization from linear polarization from circular,ellipsometry, optical Epumping, suppressing unwanted reflection and optical isolation. Zero Order waveplates are generally preferred since they are least sensitive to variations in wavelength, angle of incidence and temperatute. Air-spaced crystal quartz waveplates are also available. Its performance is as good as cemented zero-order waveplate. Additionally, the air-spaced construction enables it is suitable for the high power laser application. The damage threshold is more than 500 Mw/cm2.

Analysis of Effective Bandwidth

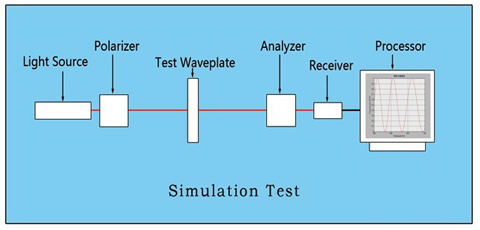

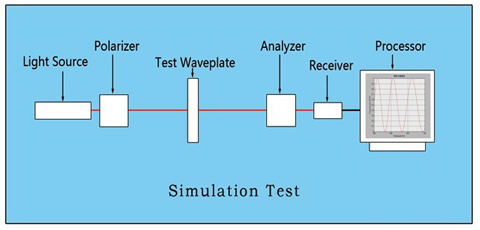

In order to analyze the effective bandwidth of waveplate, we make the following spectrum system test in lab.

In application, when linearly polarized light pass through one waveplate, the outgoing light will be elliptically polarized. The factors which affect the axis length of outgoing beam are: polarization situation of incident light (polarizer's T/R extinction ratio) precision of waveplate, fast axis orientation of waveplate, temperature of wavplate and etc. And the factors which affect the waveplate precision are: orientation precision of crystal axis, thickness of waveplate, parallelism of waveplate, purity of waveplate. If we setthe length of long axis as P while short axis as S, we can consider the incident polarizedlight as P=1, S=0. Then theoretically, the outgoing light will be P=0, S=1 through a halfwaveplate and P=1,S=l through a quarter waveplate.

Take the half waveplate with 632.8nm wavelength for example, if we put the analyzerand polarizer in parallel, then theoretically the weakest intensity spot should show at632.8nm on processor. The error between weakest intensity spot's wavelength and632.8nm is exactly the error of the waveplate (the system error can be less then 0.3nmafter adjustment).

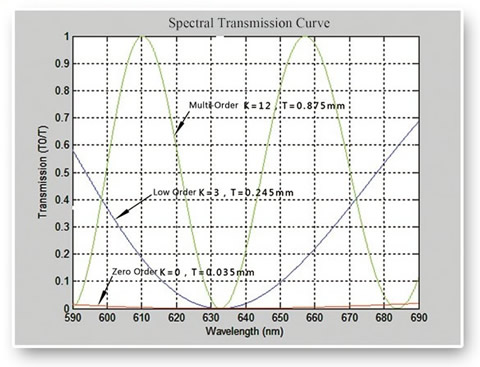

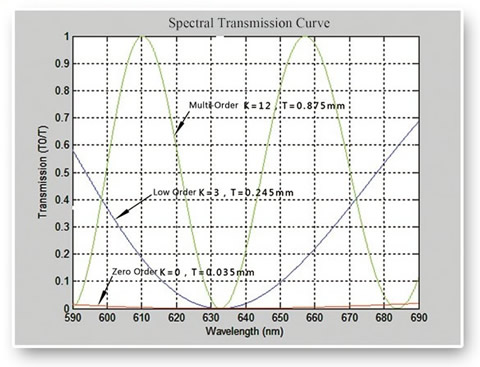

The ratio between system's maximum light intensity and certain wavelength' s lightintensity is called this certain wavelength's light ratio, Take light ratio>500:1 of 1/2 ZeroOrder Waveplate and light ratio=1:1+1/250 of 1/4 Zero Order Waveplate as reference, wecan get the theoretical effective bandwidth (actual effective bandwidth is smaller thantheoretical).

Different Bandwidth of 1/2 Waveplate of MultiOrder/ Low Order/ Zero Order

Our waveplates are classified into multi-order, low-order, zero-order, true zero-order wave plates and achromatic wave plates and dual wavelength wave plates by the thickness or order of the phase retardation. We uses laser-grade crystal quartz to produce them. In order to making them suitable for high power applications,all of our waveplates and waveplate assemblies are adhesive free. Please feel free to read the review of Comparision of defferent Waveplates.

To suit different applications, air spaced, glued or optically contacted Zero order compensated phase retardation plates are available. |

|

|